|

12-33 Brake line placement on International based cars Safety issue This report was received from thoe owner, Wayne in Feb. 2017. Bold and color emphasis added by the Annexmaster Had the first semi-breakdown in #141 in the 11000 plus miles since I have owned it (Current mileage is 67600). On Thursday evening about fifteen miles into a fifty mile (one way) jaunt on a four lane separated highway, the brake line that runs aft along the Scout 800 frame ruptured at the farthest aft attachment point. It caused a fairly abrupt total loss of brakes. I was able to safely slow down, turn around and head back home using the engine/driveline and emergency brakes to make stops. As a former professional failure investigator, I was very curious to determine the root cause of the failure. Additionally, I wanted to know relative to good corrective action, whether it might be time to replace all the brake lines, not just the failed one. My brother, Dave, owner of #162, happened to be along with me. Back home, after jacking the Glassic up so all of the undercarriage could be inspected, by replenishing the brake fluid reservoir, the substantial leak was easily found in the location above, when Dave actuated the brake pedal. Removing what appeared to be the original line from the front and aft junction points plus the frame attachment points took a little doing. An IH tube nut wrench, MT-7450, was not available, the fittings at the junction points were loosened and unscrewed only after a vice-grip was carefully employed. No heat was used, but the 3/8 " hex fittings warped and rounded off with use of open end wrenches. the line could have been sawed off, so a box end or impact socket could be applied, but wanted to keep the line intact as possible when getting a replacement. The self tapping attachment screw/bolts (going into the frame) did not loosen with the use of a manual impact driver/flat screw head, so the coated flexible attachment clamps were lightly tapped to flatten them far enough away so a 3/8 "hex socket could be slipped onto the screw/bolt heads. A little judicious tapping on a beaker bar handle then loosened the attachment screw/bolts. After cutting off plastic zip ties holding the aft running electrical lines to the brake line, that line was easily removed intact and taken to a local Autozone parts place. My brake line measured a touch over seven foot, two inches from flange to flange along the centerline. General lengths of brake tubing were available to be cut to length along with the loan of a cutting/flare tool, plus new fittings. The alternate of two unequal length pre-flared lengths of tubing that with a use of a union gave an overall length only two inches in excess made it an easy decision to just return home with the pre-flared items, etc. The new line was shaped to the old using a Black and Decker portable workshop tool to hold them together during the bending. Various diameter pipes were used for some bends; the rest were done by Kentucky windage. This shaping was done from the front to the back, leaving the last shaping very general using the excess two inches to advantage in making those gentle curves. The purpose for doing that was to begin the re-installation from the front, continuing along all the frame attachment points to the key last one. The original brake line had not rusted out, but it had been severely kinked at that last frame attachment point during assembly. The kink lasted for more than fifty years before it ruptured, but it had made things exciting for a short time when it did. By shaping very accurately from the front and attaching in that order, the final shaping through that last attachment clamp was easily done. The line at the point was basically kept straight and the brake line beyond was kept firmly in that relationship as the gentle curves were finalized so the rear fitting could be threaded into the rear junction attached to the body. Geometries were carefully taken into consideration to assure no contact under extreme suspension deflection. Manual brake bleeding, with brother Dave topside and myself doing the bleeder valve honors, then followed, but was not quite so simple as just stated. The bleeder valve OD is very small to create a clear attachment tube leading to a clear reservoir, the following had to be used. A clear plastic container, a two foot length of Autozone .25" diameter fuel line and segments of two sizes of drinking straws were put into use. An Autozone .125 diameter fuel line had been purchased to use, but was just a little too small to expand up over the bleeder valve output port. The .25" diameter line was too large, so two sizes of drinking straws on hand were used. One was slid inside other and both slid inside the .25' diameter clear line. A far better connection could/should be done, but I was doing what I could with what I had, where I was.The special IH bleeder valve tool (no number given in the manual) was not on hand. It was determined that an open end 1/4" wrench could be used to do the bleeding. One last little surprise was that to have the flares on the new brake lines seal properly, the fittings had to be cranked within an eyelash of stripping the threads. Of course, all hot-rodders know this precise torque amount from experience and muscle memory. The manual bleeding process was leaked a little until the right amount of torque was applied. The thought of replacing all the fifty plus year old brake lines was shelved after checking the rest of them for kinks and none were found.

The root cause for the kink could not be ascertained with certainty. It

could have happened on the IH chassis assembly line at Ft. Wayne. Since

these special partly assembled chassis' had to have been shipped to West

Palm Beach with the last attachment points not done, until the Glassic

body was installed, the kink could have occurred at anytime until that

rear attachment was completed at West Palm Beach. So the bottom line for all IH Glassic owners: (Generation 1), you should check your rear running brake line at that last attachment point where the line starts running up over the frame rear axle hump to make sure where the brake line leaves the clamp that there is not a kink in the line. If so, replace the line, using some of the tips above, as you like. Don't fail to do this. My kink lasted for fifty plus years, it is true, but I don't think you need the excitement I had on Thursday.

12-44 Convert to front disc brakes on a 1973

January, 2019 - George, the owner of car 876 reported:

Calipers -- L4020 Metric Calipers (these are the best most common to

use)

Rotors -- 7032RGS Brakes Best from O'Reilly Auto Parts

Outer Bearings with races -- National LM12748 (A34 - with race)

Inner Bearings with races -- National L68149 (A17 - with race)

Bearing Seals -- National 4148

Annexmaster note: It sounded

like the above project was not finished, yet, so -- also, no mention of

"proportioning valve" - which may be needed

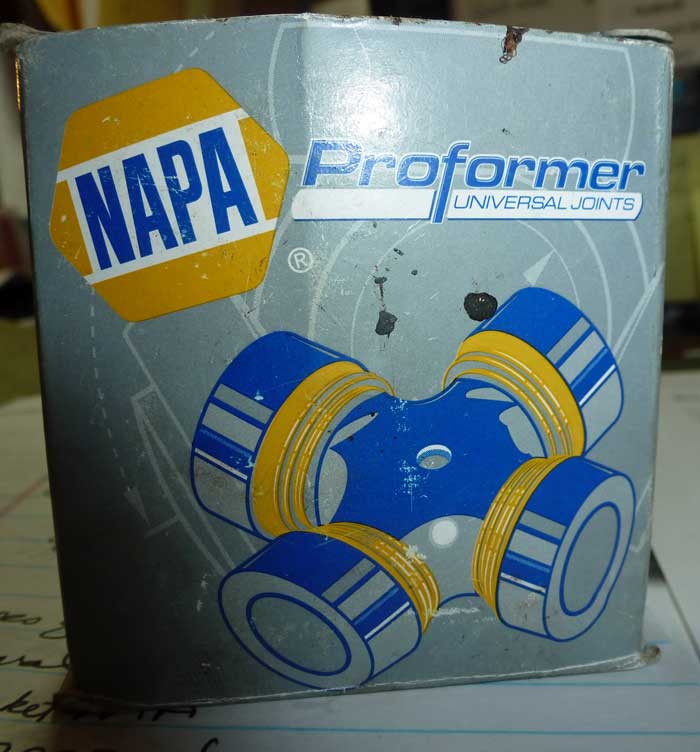

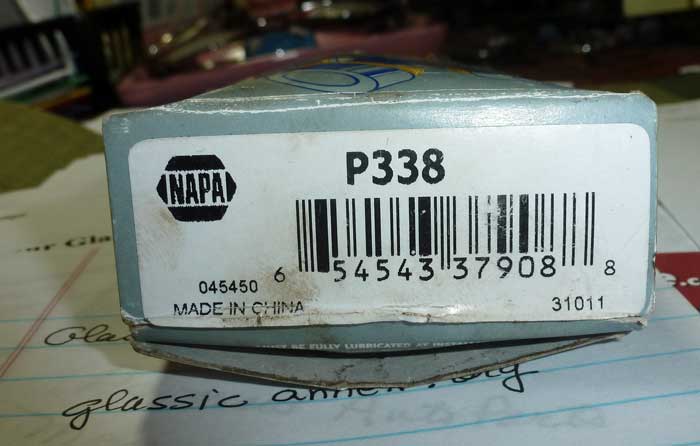

13-01 Steering column U-joint or Universal joint In March, 2014, the owner of car 691, a 1973, found a

universal joint that was a direct replacement for the one on his

steering column.

The cross reference says this part P338 fits 1961 to 1967 Dodge trucks and 1988 to 97 Ford trucks. U-Joint Length (L Dimension) : 0.94" Dia. x 0.94" Dia Brg Dia. x 1.37" x 1.37" Between Grooves It is unlikely, but not impossible that the original was a Dodge part, or this could be a totally different part with the exact measurements.

13-01-2 Sway bar end links (1979 Phaeton) info received June, 2017

Here is a picture of that part number from the NAPA on-line website

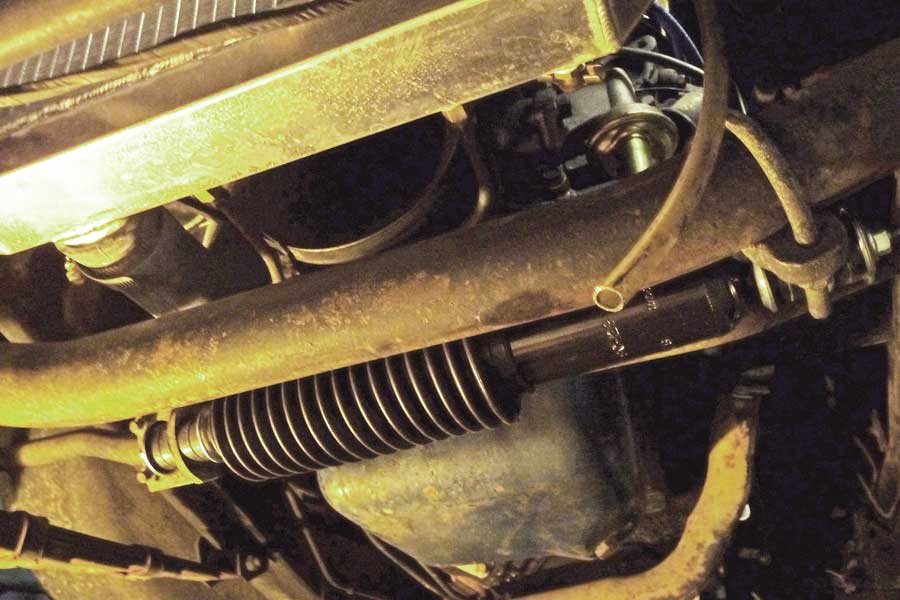

13-20 Steering Stabilizer In 2012, Car 715 reported this source info and photo for a steering stabilizer: from 1973 car #715 In 2015 car 1178p (a 1974 Phaeton) sent this

stabilizer info

Well, the parts arrived after a few days from Amazon - two different vendors - and the new part looks just like the picture. HOWEVER, unlike the report from Car 715, my car had a minor issue that I had to fix. The new and old stabilizers look the same, but did not install the same. I am still not quite sure why, but the OLD stabilizer was about half way extended when the car wheels were facing forward. The new one, was nearly all the way closed in. The math does not seem to work since the housing is the same size on the old and new. The problem is, that when the rod end is connected to the wheel end, that rod goes back and forth as the wheels turn. With the new stabilizer in the same place, turning right pulled that rod toward the driver's side - well the stabilizer was almost fully closed, so it the rod could not go anywhere. I could turn right, but barely left at all. With my mechanical skills, that could have been a solution, but it meant some serious planning of trips. SOLUTION - I moved both end of the mounting brackets further apart about an inch or two each, so that the rod, when I was finished was about half way out, like the old one had been. The issue, as close as I can tell, is that the new washers are the common fat ones (see the picture on the box below) and all of that takes away from the wiggle space between the two mounting posts. The old stabilizer had skinny rubbert washers, or worn out ones. In any event, after moving the mounts apart, the car seems fine. I have only taken it around the block, and will report here only if a longer trip shows up any problems.

Then, in a display of mechanical ignorance, your Annexmaster went out to see why HE did not have a steering stabilizer. Oops, I do have one and here is where I found it on my car 689. My Google search of Bronco stabilizers looked like they were in FRONT of the axle where ours are behind.

Taken from under and behind the driver's side front

wheel, looking toward the front of the car.

Left: looking down under the hood at the driver's side

end Right: looking up from the ground at the passenger side end.

This is the new stabilizer in place with the dust

cover. This was before I moved the mounts further apart. You can't see

anything, but you can guess that not much of the rod is exposed under

that cover.

14-01 Suspension - rough ride fixed

**********************

14-03 Suspension - International springs re-done In January, 2012, Stan, the

owner of car 106, had spring work done on his Southern California

Phaeton.

Note: While it is general

knowledge, I think, it is worth mentioning that RADIAL tires will

significantly ****************************

15-55 Rear Ends and Gear Ratios General info - (or rear ends for dummies)

1966-71 cars: This info This info relates to International based cars - the first generation of Glassics. Some of these cars ended up with V-6 and V-8 conversions, which would affect the engine speed and performance in relation to the rear end gearing. Car 313 -- in May, 2010 Bill Crozier wrote, regarding his car with a Chevy V-8 swap. Originally he kept the rear end that came with the car (and its 4 cylinder engine). I changed the rear end gears in mine and what a difference it made its a real car now the gears are still available to just change the ring and pinion changed the whole car for the better went from 373 (factory) to 308 boy oh boy easy fix with out mods. Bill's son, Dennis, who owns car 189, also with a V-8 swap wrote the following, also in May, 2010: My dad just had his (car 313) 3.73ís swapped out with 3.08ís and said it made a world of difference. Mine is a little older with the pumpkin a little offset to the pass side. If the numbers are good and I can get the gears, Iím gonna do the same swap. Maybe at 60 MPH it wonít sound like itís gonna blow up.

Chevy S-10 Rear end change after a V-8 swap into an International car (# 189) Reported to the Annex in 2012: I ran into some issues

recently during a gear change....

a 1973 car:

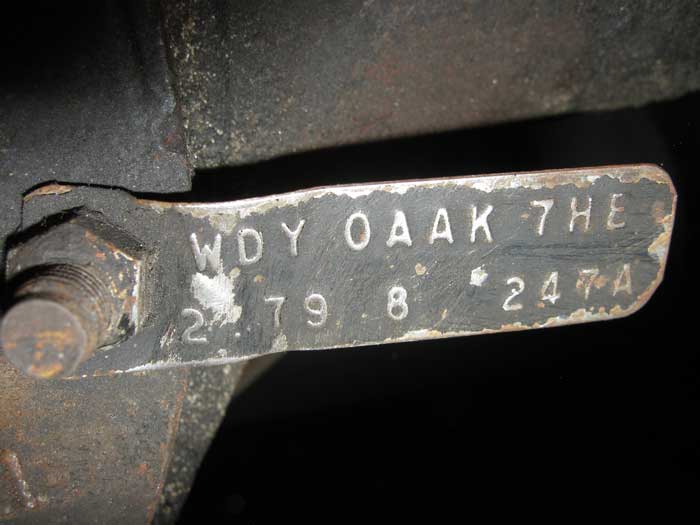

WDW-U axle model: - in this case: "Comet- Maverick 71 - 77 8 inch, non locking, 28 spline. - the 2MC has to do with "interchange" - or sub-model? 3.00 is the gear ratio, 8 is the date, according

to the chart, but it IS an 8 inch, so maybe that is what this # is

In conclusion, it appears that the metal "dog tag" has the more useful information, especially since it includes the GEAR RATIO. a 1974 car: Rear end and gear ratios. -- part of the info below also appears under AOD (overdrive) transmissions.

1978 cars: The Annexmaster then checked his 1978 - car 1254 and saw the info below. This tag was on the passenger side of the car, on the side of the hub facing the front of the car, and it was upside down - I reversed the picture.

WDY OAAK 7HE 2.79 8 247A http://www.woodyg.com/fairlane/finfo/fordrears.html http://www.fordmuscle.com/forums/all-ford-techboard/470670-ford-rearend-axle-tag-codes-posted.html The numbers on this tag seem to only somewhat relate to anything on the above websites. The WDY code has an AA (1976-78 Mustang 3.0 gear, 8" ring gear)

The 7HE is a Ford internal code which I guess is not important to us.. Further discussion of rear ends should address the impact of using a different rear end ratio. What happens to gas mileage and acceleration if we were to change the 2.79 ratio to a 3.0, for example? *********************** Rich, car 1148, looked up my numbers on the 1978 and came up with the following: I have examined your tag.. I came up with as follows.. WDY is actually Maverick (Joel the builder HAS mentioned the use of Maverick parts in the past) OA is limited slip -- OA is for limited slip not a popular option.. Most were either open diff's or they had an L which was for traction lock.. 7HE threw me but I came up with-- 7=1977 H= August E= 5th week -- Now there were 5 weeks in August 77 I had to go look it up. 247A is plant serial number .. . I hope this helps.. This appears (to the Annexmaster) like reading tea leaves. A quick check of the web did NOT find these codes on sites listing the various Ford numbers. If my car, 1254, HAS limited slip, wow, because I can make it spin the tires by just looking at it wrong! Not all sites seem to list the same codes for the same cars. And the ones I saw did not show the date on the upper row of the tag. Rear end identification does not seem easy to do. |

||||

|

Replacing the steering rack - Info from Mark, car 1290, (a 1978-79) received 4/2008. See many upgrades on his car project. Well I am in the process of replacing the steering rack. And guess what my Mustang II front end has a Pinto rack on it. Pintos used a 9/16 26 spline input shaft and Mustang used a 3/4 30 spline mine was the 9/16 unit. I am replacing it with a FlamingRiver 3/4 30 spline unit all Chrome and I taking off the power steering and going manual. So if someone is replacing their steering rack they need to check the size spline and number of teeth if they want a direct replacement. 6/2008 -- When the Annexmaster asked Frank (car 1505) about how his car "tracked" at high speeds, thinking that I might want to adjust the toe-in, he replied:

|

||||

|

Steering Column: International 8/2008 -- An owner wrote that she had bought a replacement steering column from a Scout, and that it was fine, but way too long and had to be shortened. When I wrote to Joel, the builder, to ask about this, I got the answer below, which does not address length but another issue. I am trying to get clarification on all this, but want you to know that it is not a direct replacement as I would have thought.

I still had questions, so I asked the builder to explain further:

|

||||

|

1973 cars, front end. Also engine specs From Joel, the builder, in Dec. 2008 regarding the Annexmaster's purchase of car 689, a 1973 Phaeton:

|

||||

|

Steering box on an early 1977 with the leaf springs My 1977 #1100 has front leaf springs . what type steering box might it have ?

In October, 2010 Jim, owner of a 1973, sent the following:

|

||||

|

Leaf spring in front end changed to coil-overs

|

||||

|

Rear Springs in a 1974 or similar A

question was presented to the message board in April, 2009. Since Rich,

car 1148, had tried Does anyone know what springs were used in a 1974 roadster (REAR). I need to replace the spring eye bushings and every attempt at ordering ford replacement parts has come up with the wrong ones. Any help would be greatly appreciated. I have tried Bronco, Pinto, Maverick, LTD, Mustang, Econoline, F150, I am trying to find a picture to see if international might look right..

Later on, the builder added:

Further information received in May, 2009 on this subject from Rich, car 1148

|

||||

|

17-01 Flywheel installed wrong originally In August, 2011 I took car 689 (a 1973) in to a

transmission shop for service. The trans had been leaking in several

places That, of course, is due to the extreme age of our cars

and the fact that there are tons of rubber parts in a transmission I was told I needed a new flywheel ($100 bucks

or so) since the original one had been installed wrong and

I will describe what I was told and what I saw on the

one they took out. The flywheel is a big flat metal disk ALSO, there are two larger holes in a bit from the

edge -- and THOSE are so that the drain plugs, or bolts I could see scratches on my old flywheel where it

likely scraped or bent when the flywheel was tightened down. I did not see the old or new flywheels in place, but I

was told that one can open the viewing panel I will try to draw out the bolts and holes x

x O O x

x You can see that if you turn this pattern 90

degrees, the four x holes still align, but

the |

||||

|

17-02

Changed column shift In March, 2009, John, the owner of car 1254 reported:

|

||||

|

17-02 -- Floor shifter on a 1973 loose and wobbly Start by remembering that your Annexmaster is NO KIND of mechanic, so this info may be overly simple. When I got car 689, the floor shifter was loose and wiggly, and although it worked ok, it felt like it would lift right out of its socket on the floor. Here is what I learned. First, this is a common old Ford floor shifter and so answers can be found on the internet. There are a few helpful hints I learned about Glassics and these shifters. First, there are BUSHINGS that keep the handle firm, and mine were totally GONE. A common problem, apparently. I found this video in July, 2010 which helped put me on the right track. http://averagejoerestoration.com/how-to/how-to-replace-mustang-automatic-shifter-bushings/ IN GLASSIC CASES, IT IS EASIEST TO NOT REMOVE THE SHIFTER BOX FROM THE CAR IF IT IS NOT LOOSE.

above: two bushings needed, but they shipped me 3. First, in our Glassics, the shifter is attached differently from the Ford video. My first mistake was to remove the chrome cover and try to loosen the 3 bolts in the fiberglass base. That did not work like the Ford because the shifter box is bolted to the fiberglass base piece, which is then pop-riveted to the floor. When I loosened the bolt, the nut on the bottom merely fell off and disappeared. So the three mounting bolts go down through the fiberglass housing, with a nut directly below the fiberglass piece, to hold it firmly in place, and then another nut is installed from under the car to hold the metal shifter box . The article about the shifter bushings is temporarily interrupted at this spot to answer a question raised in 2015 - namely: WHAT IS THAT MOUNTING STRUCTURE BETWEEN THE SHIFTER & THE TRANSMISSION HUMP? The Mustang shifter in the original Mustangs was

mounted directly on the floor of the car. In our Glassics, it is raised

up on

Since there is no room to reach that nut under the car, it is likely that the whole thing was assembled outside the car and then the base piece was installed into the car. So I cut the opening in the bottom of the car larger so I could get a wrench (and my fingers) up in there to re-install the bolts. If your unit is bolted firmly in place, there is no need to mess with that part at all. In my case, I was able to install the bushings without removing the shifter box like they had done in the video. After failing at a couple of local parts places (I thought that NAPA had everything!) I ordered the bushings for $6 incl. postage from the people who did the video. (ad at the bottom of the web page with the video) I also saw them on eBay. Ordered on Wed., postmarked on Sat, and got here on Monday. There was no communication from them after I sent the PayPal, so I was glad they actually got here. There were 3 of them in the bag, but I think that was just a mistake. They were thinner than I expected but worked great to tighten up the handle. Each has a slit in it so you can lift it over the shaft without having to fully remove it from the car. NOTE -- there are two ground wire connections that I found - remembering that our cars are fiberglass -- first, one of the bolts that holds the box in place has a ground wire attached to it under the car, held on by the nut. When I tried to loosen the bolt from the top, that nut fell off, and the ground wire just hung there -- I think that is why the car would mostly not start -- that neutral safety switch was likely just barely grounding. The other ground wire was attached to the black curved piece that provides the background for the shift pointer. That one was for the light inside the shifter box. The set screw that held on the shifter T handle was totally stuck on my car, and I had to use a screw extractor to finally get it loose. It must be a common part since I found a new set screw in my junk box. Grease those bushings as the video suggests, and they do fit in the opening nicely, one from the inside of the box and one from the outside -- however, you may want help inside the car, as the second one wants to push the first one out of place. My wife ended up using a box end wrench inside the car (also, the offset box wrench was how I loosened the bolt holding the handle on) -- anyhow, she used the wrench to hold the inner bushing in place while I wiggled the shaft and outer bushing till it finally slid nicely into place. |