| In 2016 Tony, the owner of car 1452, - in the Oakland California area -- addressed a number of items. Car 1452 photo | |

|

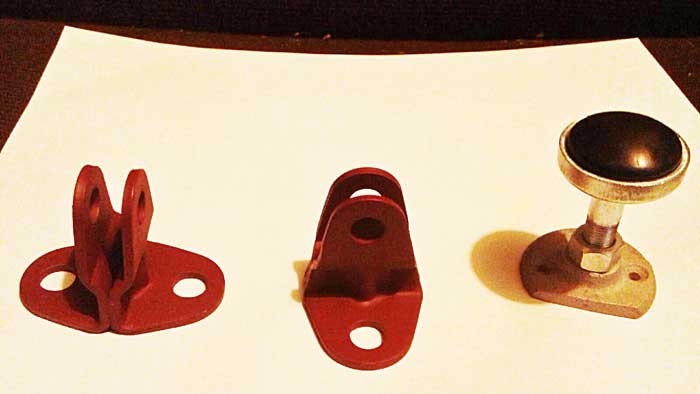

Passenger seat brackets. Tony found a Model A replacement part and

ordered a pair of them. While they looked good, the fit was not an exact

match, so he ended up having a pair made.

above left: the original bracket -- above right: store-bought Model A replacement brackets, and a foot rest pedal (so you don't rest your foot on the dimmer switch.) The base of the swivel mount is almost exactly as the existing part.

The height of the vertical member is too high and the hole is too big

and is located too high. The store bought seat hinge mounts were cheaper than the fabricated

ones. above: new, custom-built heavier brackets. Pins used instead of nuts and bolts. Heavy, solid construction. |

|

|

Turn signal arm shortened

I had the indicator arm shortened to give space for my left knee.

I am 6'4" tall, about 200 pounds

|

|

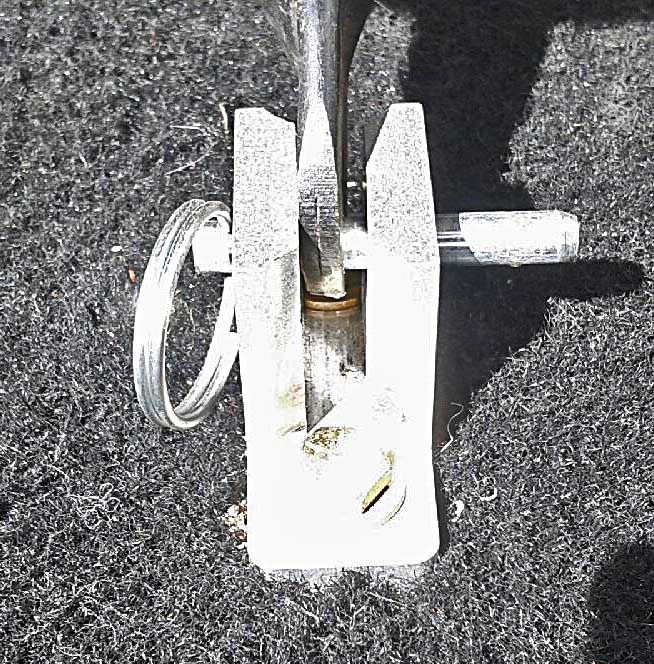

| Steering Rod Vibration Dampener new one

added -- as best as I can photograph

it.

|

|

|

Brake Pedal Moved

I have size 13 feet, I had the foot rest installed and also had the brake pedal moved over, so that my left foot does not interfere when I have to apply the brake. The pics show the original brake pedal- reinstalled following the modification. I am seeking a smaller brake pedal, but what I have now works fine. |

|

|

Driver's Seat Mounts Moved

I am 6'-4"

tall.... I had the drivers seat shifted back 5 inches, along with the

seat (lap) belt.

The seat belt is now mounted as far back as it could go. Still on the

inside of the left side of the car; against the wall under the back

seat. A new metal bracket ties the seat belt to the frame in the same

way as the seat belt was originally manufactured and mounted.

The silver domed bolt heads cover the old holes in the floor, where

the drivers seat was originally mounted.

Now, when I push the drivers seat into the fully back position, the

rear of the drivers seat sits about 2 inches in front of the rear

seat.

When the seat is in the fully forward position, it feels to me like it

used to, before I made this modification.

|

|

|

New knobs fabricated.

The knobs (on the dash board) to the air conditioner were both broken

when I purchased the car.

Mr. Shinnick manufactured the knobs photographed below from a block of

aluminum. (See the box at the bottom of this

page)

|

|

|

Hood Side Panels reinforced.

My car suffers from "rattling" to take some of that away each side was

stiffened with two flat steel sections; screw fixed into the engines

side curtains. Stainless steel washers and screws (with lock nuts) to

match the row along the trailing and leading edge. As shown in the

attached pic. I don't think this alteration looks to, "out of place".

The stiffener for the side panels were fabricated as two parallel bars

that do not touch each other, Click on the pictures for a larger view |

|

|

Mr. Joel Shinnick manufactured several new parts:

Two Pivot mounts for the passenger side seat out of aluminum, Two Air conditioning control knobs out of aluminum, The above items were about $50 each item. Contact Mr Shinnick for a quote if you are interested. Bushings for the door hinges out of medical grade plastic - he tells me these ware better than the original brass bushings.

He also machined the steering rod to accept the new steering vibration

dampener - which works perfectly.

Now the car shakes with pot holes and bumps in the road - but not the

steering wheel.

Joel tells me that he has recorded the patterns for the parts that he

manufactured so that he can reproduce them for anyone who wants them.

|